Project Overview

This rail infrastructure project in New Zealand formed part of Auckland Transport’s Level Crossing Removal Programme, delivering safer station access for the local community at Homai Station.

The site sits adjacent to BLENNZ School Homai (Blind Low Vision Education Network NZ), Blind Low Vision NZ’s South Auckland office and Guide Dog Training Centre), meaning accessibility and user safety were central to the design. Dura Composites Australia was appointed to deliver a safer and more inclusive alternative to the hazardous level crossing and outdated stairs, whilst providing a modern, sustainable alternative to traditional materials.

Throughout the programme, the Dura Composites Australia team provided practical, on-the-ground support, working closely with the design and delivery partners to ensure smooth integration of the d² GRP solution into the local rail environment.

A ‘Bridge-in-a-Box’ efficiently and sustainably delivered.

Traditional design would have required 10-metre spans of precast concrete ramp sections weighing 30 tonnes, supported by seven pillars. Instead, we delivered 15-metre spans on a steel substructure weighing only 8 tonnes, made from recyclable materials. This resulted in a 50% increase in span and a 73% reduction in weight.

Our lightweight design allowed all core GRP materials to be pre-cut, drilled, and efficiently packed into a 40ft container, earning the nickname ‘Bridge-in-a-Box’. This approach minimised crane size, avoided road closures, and eliminated up to 39 heavy goods vehicles from the project. The reduction decreased roadwear, minimised disruption, and prevented 624 tyres from releasing microplastics into the stormwater drainage system.

By completing cutting and drilling at manufacture, the 90-metre modular structure was prefabricated in 15 metre sections before being lifted into position via crane. A unique code was etched onto the side of each panel, corresponding to a location detailed in the installation plan to aid assembly. This allowed offsite work to progress while groundworks and piling took place, enabling faster completion and minimising disruption for local residents.

Inclusive design for the community

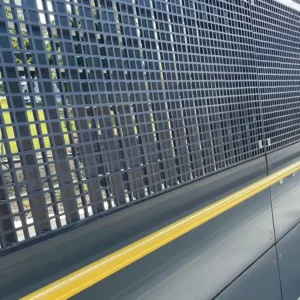

BLENNZ School Homai formed part of the consultation group, along with local community, to ensure the upgrades to Homai Station would benefit those who use it. As a result, the bridge incorporated an alternating colour scheme to help people with low vision differentiate between flat landings and sloping sections of the ramp. In addition, bright yellow contrasting handrailing was specified to support safer wayfinding.

Results & Impact

The safer access at Homai Station replaces two pedestrian level crossings which are now closed as part of Auckland Transport’s broader programme of replacing level crossings to support more frequent trains while improving safety and keeping roads moving.

The new bridge achieved:

- 123 tonnes of carbon savings, equivalent to 369 flights from London Heathrow to Dubai, planting 5,583 trees, or driving 584,843 miles in a diesel car.

- A 50% increase in span length and 73% reduction in weight compared to concrete.

- A reduction in groundworks, with only five support pillars required instead of seven.

Timely execution was critical, and the project demonstrated strong collaboration. Alongside Auckland Transport, Scartan Consultants, Darlo NZ, Beca Design, Downer and PFS Engineering, the Dura Composites Australia team provided practical technical input, responsive problem-solving and on-site guidance to help accelerate delivery.

Unlike traditional materials, the modular d² Bridge-in-a-Box design also means that the structure can be dismantled and reused elsewhere along the expanding rail corridor over the next 15 years. This project stands as a testament to what can be achieved under pressure and it has been a privilege to collaborate with organisations that consistently challenged convention and accelerated delivery.