Dura Composites has experience in the design and supply of GRP product solutions for external infrastructure and depot works.

Our non-conductive, non-corrosive and durable product ranges are ideal for renewing or upgrading facilities to meet the changing needs of train operating companies.

Thanks to the lightweight nature of the materials and their ease of manoeuvrability, works can be easily undertaken without impacting on operational safety or the running of services which rely on these facilities every day.

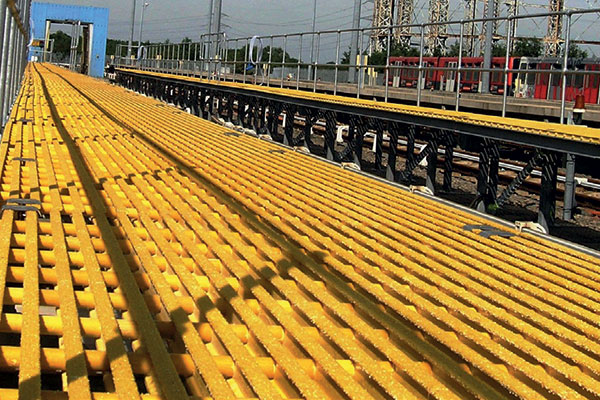

Our gritted anti-slip walkways for examples are the ideal safe access to external fuelling areas, CET stations and wash-plant facilities. Made from our d2 Dura Grating they are an ideal and cost-effective alternative to traditional grating materials like wood, galvanised steel and stainless steel.

The grating is exclusive to Dura Composites and cannot be found anywhere else . It has been extensively anti-slip tested using methods far superior to those of other GRP grating suppliers, achieving anti-slip scores of more than 63 in the wet, maintaining low slip potential even after 1.1 million footfalls.