GRP is widely acknowledged as a material that has major advantages over more conventional options such as wood, steel and concrete. It is less energy-intensive in development and offers a great strength to weight ratio, and superb lifecycle.

But it’s not just the initial outlay costs that you should consider when deciding on a material for your project. It’s important to consider the whole lifecycle of the material and all its associated costs, including installation, how long it will last and what kind of maintenance (if any) it will require to keep it functioning and looking its best.

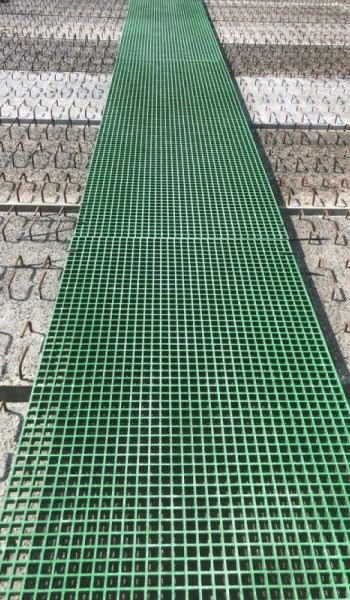

Dura Composites’ GRP products offer considerably low life cycle costs due to their maintenance-free, corrosion-resistant and impact-resistant characteristics compared with traditional materials, and market leading products such as Dura Grating come with a reassuring 25-year warranty and a design life of up to 60 years.

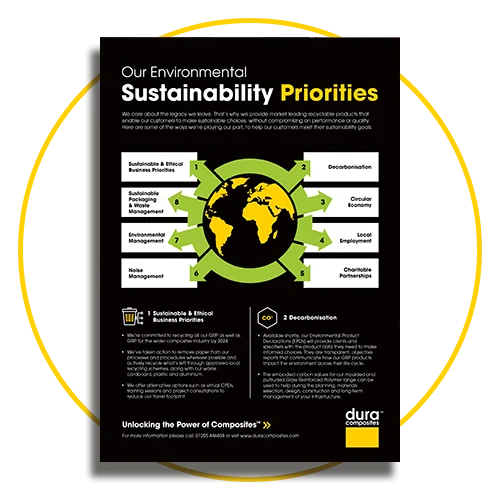

A circular economy is one that keeps materials in use, at their highest value, for as long as possible. It does so through products designed to be long lasting, easy to repair and recycle, and through systems that allow for the material to be re-used, repaired or recycled.

Re-use is the most economically and environmentally beneficial strategy within a circular economy. Finished products are worth much more than the raw materials they are composed of and direct re-use preserves the most value and embodied energy.

In the case of our Dura Grating panels for example, even after they have been used for their intended purpose and reach the end of their lifecycle in the original context, they can easily be up-cycled or repurposed in other ways.

Dura Composites operates upcycling which offers goods for use in additional non-standard applications as part of our commitment to upcycling and encouraging re-use and re-purposing of our materials wherever possible, taking advantage of their inherent durability and other properties.

Secondary uses include 4×4 sand ladders, caravan jack pads, stair treads, building site flooring, seedling plant separators, lorry jacks, drain covers, shelving and racking, car parking matting, and farm land access grids – the possibilities are vast and we are happy to advise all customers on their specific scenarios.