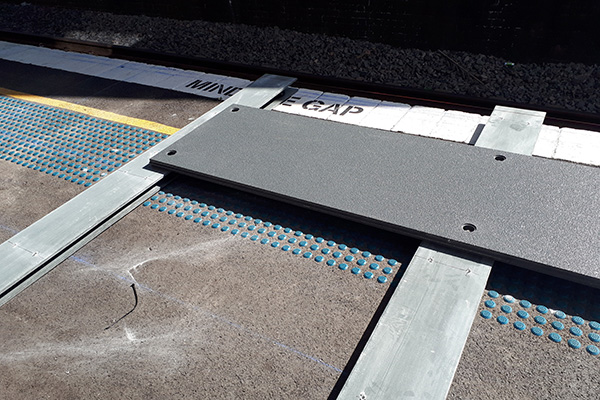

Project: Victoria Street Station, East Maitland, NSW, Australia

Client: NSW TrainLink, with Downer Group and Arcadis working with Dura Composites Australia

Opened in 1857, this heritage-listed railway station and remnant of the early line, is a hugely significant landmark for local people.

Due to the evolving nature of train heights which vary the platform interfaces, this national icon needed an upgrade that needed to raise the platform in sections to counteract the high risk to passengers. A raised 45m hump section was proposed to create level boarding for the varying trains which stopped in the station.

With the ageing of the platform, the surface had become uneven, so the requirement of a modular, lightweight, adjustable and self-levelling overlay platform was required.

This project needed to be delivered quickly to avoid disruption to passengers, which is why Dura Platform 40 lightweight nature made it perfect for the job with its manual handling, eliminating the need for costly Hi-rail plant or heavy lifting equipment and being able to achieve an instant 1:40 fall to manage drainage, whilst being crankable.

Dura Composites modular pedestal system was built off site to suit the varying heights of the uneven surface of existing platform, managing to raise the height to nearly 300mm on the copping edge plus creating the fall required for the humped section of the platform. The platform 40’s cleverly designed hidden fixing system also minimized trip hazards.

Downer Group and Arcadis working with Dura Composites successfully delivered the 45m raised hump section in February 2019, and it still looks as good now as it did then, despite the harsh prolonged exposure from the sunlight.

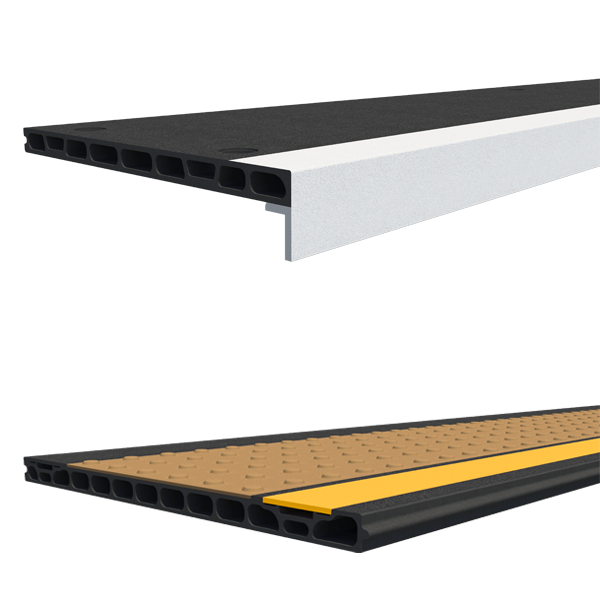

The 40mm Dura Platform solution has a span of 1.5m per 5kN/m2 UDL and delivers multiple benefits in terms of faster, safer and easier installation, reducing time on site with less possessions required, therefore reducing disruption to passengers, and providing major cost savings versus traditional materials such as concrete, structural steel and asphalt.

The platform panels can accommodate fully integrated tactile recesses, illumination of the copping edge and reduce the future maintenance burden of the platforms, creating a more accessible and future-proof railway service.

Commenting on the project and talking about the availability of the Dura Composites range in the region, Jordan Armstrong, Business Development Lead for Dura Composites Australia Pty Ltd, said:

Following the successful deployment of our award-winning Dura Platform train station platform overlay solution at Victoria Street station in NSW in 2018, we have continued to innovate, launching a range of patented solutions. It’s great that the Dura products are now here to supply market demand in Australia and New Zealand and that we are backed with the engineering and experience these quality products bring to the many sectors.

We are sending a clear message to all our valued customers in the region that we are taking a leading and proactive approach to quality and environmental management and that we are passionate about ensuring that the lifecycle benefits of our products are widely understood. The innovative weight-reducing designs of d2 help to reduce the carbon impact on the environment, whilst the future-proof fire resistance, anti-corrosion specification and anti-slip gritted surfaces all ensure that our Australian and New Zealand customers will benefit from enhanced safety and accessibility of their structural walkways.